-

ロベルタ陶磁器軸受けは高精度、良質および安価である。私達に協同が長年にわたりある。

ロベルタ陶磁器軸受けは高精度、良質および安価である。私達に協同が長年にわたりある。 -

オリガWeinbergこの会社は私達の信頼でき、長年にわたり陶磁器軸受けの専門の製造者は、私達のポンプで使用される陶磁器軸受け、質でよい。

オリガWeinbergこの会社は私達の信頼でき、長年にわたり陶磁器軸受けの専門の製造者は、私達のポンプで使用される陶磁器軸受け、質でよい。

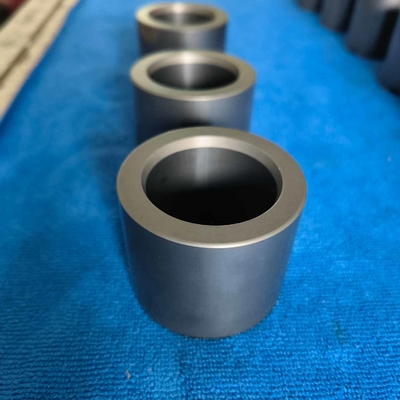

Customized SSIC Ceramic Sliding Bearing 1650°C High-Temp Resistance

試供品およびクーポンのための私に連絡しなさい。

Whatsapp:0086 18588475571

微信: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 名前 | カスタマイズされたセラミックスライディングスリーブベアリング | 材料 | 加圧焼成シリコン炭化シリコン/ジルコニア |

|---|---|---|---|

| カテゴリ | セラミックスライドベアリング | サイズ | 図面に従ってカスタマイズされています |

| 品質 | 高精度、長寿命、OEMシーリブ | 摩擦 | 低い |

| 耐食性 | 高い | 耐久性 | 高い |

| 使用 | さまざまなポンプ | パッケージ | フォーム+カートンボックス |

The silicon carbide (SiC) sleeve is precision-engineered from high-purity SiC material, offering exceptional wear resistance, corrosion resistance and high-temperature stability. Widely used in rotating equipment across chemical, mechanical and energy industries, it is particularly suitable for long-term operation under harsh conditions including high speed, strong corrosion and extreme temperatures.

Silicon carbide ceramics exhibit outstanding mechanical properties at room temperature, including high strength, hardness, and elastic modulus. They also demonstrate excellent thermal stability with high thermal conductivity, low thermal expansion coefficient, as well as remarkable specific stiffness and optical machining characteristics.

- Superior Wear Resistance: Mohs hardness 9.5, 5-10x lifespan vs metal sleeves

- Excellent Corrosion Resistance: Withstands strong acids/alkalis

- High-Temperature Stability: Maintains performance up to 1650°C

- Low Friction: Precision polished surface

- Lightweight: 1/3 density of steel reduces operational load

| Parameter | Value |

|---|---|

| Material | SSIC |

| Density | 3.15 g/cm³ |

| Flexural Strength | 550 MPa |

| Thermal Conductivity | 120 W/(m*K) |

| Max Operating Temp | 1650°C |

| CTE | 4.0×10⁻⁶/°C |

- Mechanical seals for chemical process pumps

- Rotary components in semiconductor equipment

- Bearing assemblies for molten salt pumps

- Specialized nuclear industry equipment

Our company (ZXSQ and CSQ) possesses eleven invention patents for utility models. We have a high-quality professional team of dozens of members to provide excellent service and customized bearing products according to customer requirements.

Since 1982, we have accumulated over 40 years of experience in ceramic bearing material research and development, processing techniques, and equipment improvement. Through continuous evolution, we have become a leading enterprise in China's ceramic bearing and ceramic material products market.

We operate a fully automatic grinding and assembling production line for ceramic bearings, with an annual output of 3 million sets of 608-2PS, 608-2RS and other specifications of P5 and P4 precision levels. Our facility specializes in producing various types of rolling bearings, ceramic balls, and ceramic rollers.

Our firing equipment and technology lead the industry, featuring the most advanced equipment in domestic industrial ceramics production, including a hot isostatic sintering furnace (HIP) imported from ABB Sweden. Our product firing temperature capability exceeds 2000°C.

We supply high-quality bearings and related products. For purchasing inquiries or price consultations, please contact us. As a professional bearing company integrating R&D, production, sales, and service, we carefully manufacture each bearing using premium materials.

We prioritize customer needs, striving to provide quality products and after-sales service to create value and become your trusted partner. We welcome opportunities for cooperation!