-

ロベルタ陶磁器軸受けは高精度、良質および安価である。私達に協同が長年にわたりある。

ロベルタ陶磁器軸受けは高精度、良質および安価である。私達に協同が長年にわたりある。 -

オリガWeinbergこの会社は私達の信頼でき、長年にわたり陶磁器軸受けの専門の製造者は、私達のポンプで使用される陶磁器軸受け、質でよい。

オリガWeinbergこの会社は私達の信頼でき、長年にわたり陶磁器軸受けの専門の製造者は、私達のポンプで使用される陶磁器軸受け、質でよい。

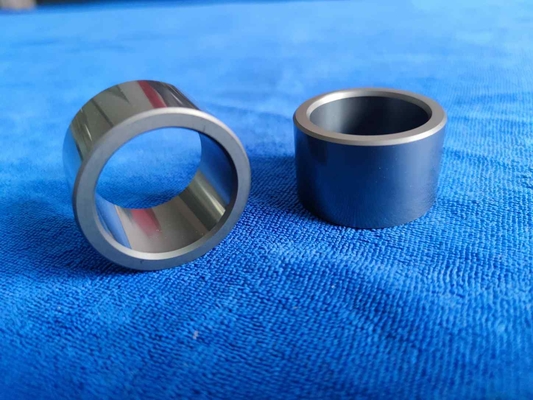

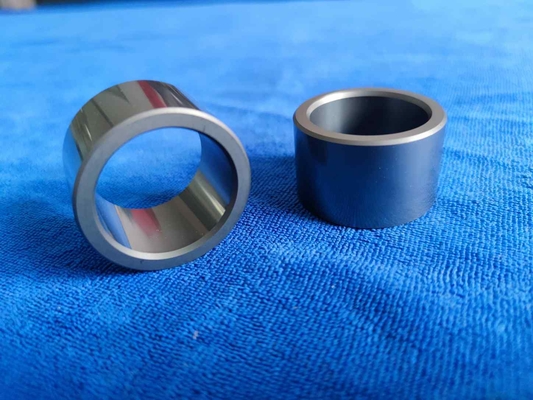

産業用自動車用航空宇宙用耐腐食性セラミックスライディングベアリング

| Name | Customized ceramic sliding sleeve bearing | Category | Ceramic sliding bearing |

|---|---|---|---|

| Material | Pressureless sintered silicon carbide | Size | Customized,according to the drawings |

| Application | Pumps | Package | Foam+carton box |

| Quality | High precision, Long life, OEM serive | Specification | Standard size and customized |

| ハイライト | 工業用セラミックスライディングベアリング,自動車用セラミックスライディングベアリング |

||

| 属性 | 値 |

|---|---|

| 名前 | カスタマイズされたセラミックスライドスリーブベアリング |

| カテゴリー | セラミックスライドベアリング |

| 材質 | 無圧焼結炭化ケイ素 |

| サイズ | 図面によるカスタマイズ |

| 用途 | ポンプ |

| パッケージ | フォーム+カートンボックス |

| 品質 | 高精度、長寿命、OEMサービス |

| 仕様 | 標準サイズおよびカスタマイズ |

セラミックスライドベアリングは、工業、自動車、航空宇宙用途で使用される高度なベアリング技術です。窒化ケイ素、炭化ケイ素、またはジルコニアなどのセラミック材料を使用して構築されており、従来の鋼製ベアリングと比較して優れた性能を提供します。

- 耐食性:過酷な化学物質や環境に対して高い耐性があり、化学処理や海洋用途に最適です。

- 摩擦の低減:より滑らかで硬いセラミック表面は、摩擦と摩耗を最小限に抑え、性能と寿命を向上させます。

- 高温耐性:劣化することなく極端な温度に耐え、エンジン部品や産業機械に最適です。

セラミックベアリングは、航空、宇宙、航海、石油、化学、自動車、電子機器、冶金、電力、繊維、ポンプ、医療機器、科学研究、および防衛産業で広く使用されています。

| 最高温度 | 最大1650℃ |

| 密度 | 3.15-3.18 g/cm³ |

| 熱膨張 | 4.0 (10-6/℃) |

| 熱伝導率 | 120 W/m°K |

| 硬度 | 2800 HV5 |

| 弾性率 | 410GPa |

| 化学的安定性 | 酸およびアルカリ腐食(フッ化水素酸を含む)に対する優れた耐性 |

- 機械的特性を維持するより高い温度安定性

- 熱膨張が低いため、温度変動に対するより優れた性能

- かじりつき防止と固着防止性能の向上

- 高真空環境下での潤滑なしでの動作が可能

- 酸、アルカリ、塩腐食に対する耐性

- 静電気のない電気絶縁性

- 非磁性特性により、研磨粒子の付着を防止

中国に3つの工場があり、高度なプレス、焼結、および加工機を使用して、多様な顧客のニーズに対応しています。当社(ZXSQ/CSQ)は11件の発明特許を保有しており、高品質のセラミックベアリング製品の製造に専念する専門チームを維持しています。

1982年以来、セラミックベアリングの研究、開発、製造において40年以上の経験を積んできました。中国のセラミックベアリングおよび材料市場におけるリーディングカンパニーへと進化し、ドイツのWitteなどの国際的なクライアントにSSiCスライドベアリングを供給しています。

- 無料サンプルベアリングをご利用いただけます

- ISO規格に準拠した生産

- 在庫ありのベアリング

- 少量注文に対応

- OEMベアリングサービス

- お客様の図面またはサンプルからのカスタマイズされたベアリング

- 競争力のある工場価格

私たちは、中国の北京にある工場で、40年以上のセラミックベアリング製造経験があり、国内外の企業と協力関係を維持しています。

量産前にサンプルを作成し、お客様の要件を厳守し、精密検査を実施し、フォーム+カートンの二重梱包を使用して製品の品質を保証します。

セラミック深溝玉軸受、アンギュラ玉軸受、ハイブリッドセラミック玉軸受、リニアベアリング、およびさまざまなセラミックボール。

3つの工場と最新の設備を備えた業界と貿易を統合した会社として、より良い納期と製品品質を提供しています。

高品質の製品、ユーザーのニーズに応じた完全なカスタマイズ、およびサンプル確認サービス。

安定した品質と価格を確保するために、原材料サプライヤーと協力しています。当社の製造技術により、必要に応じて原材料を製造することも可能です。お客様の需要が、高品質の製品とアフターサービスへのコミットメントを推進しています。潜在的な協力について話し合うことを歓迎します!

総合評価

ランキングスナップショット

すべての評価の分布は以下の通りですすべてのレビュー